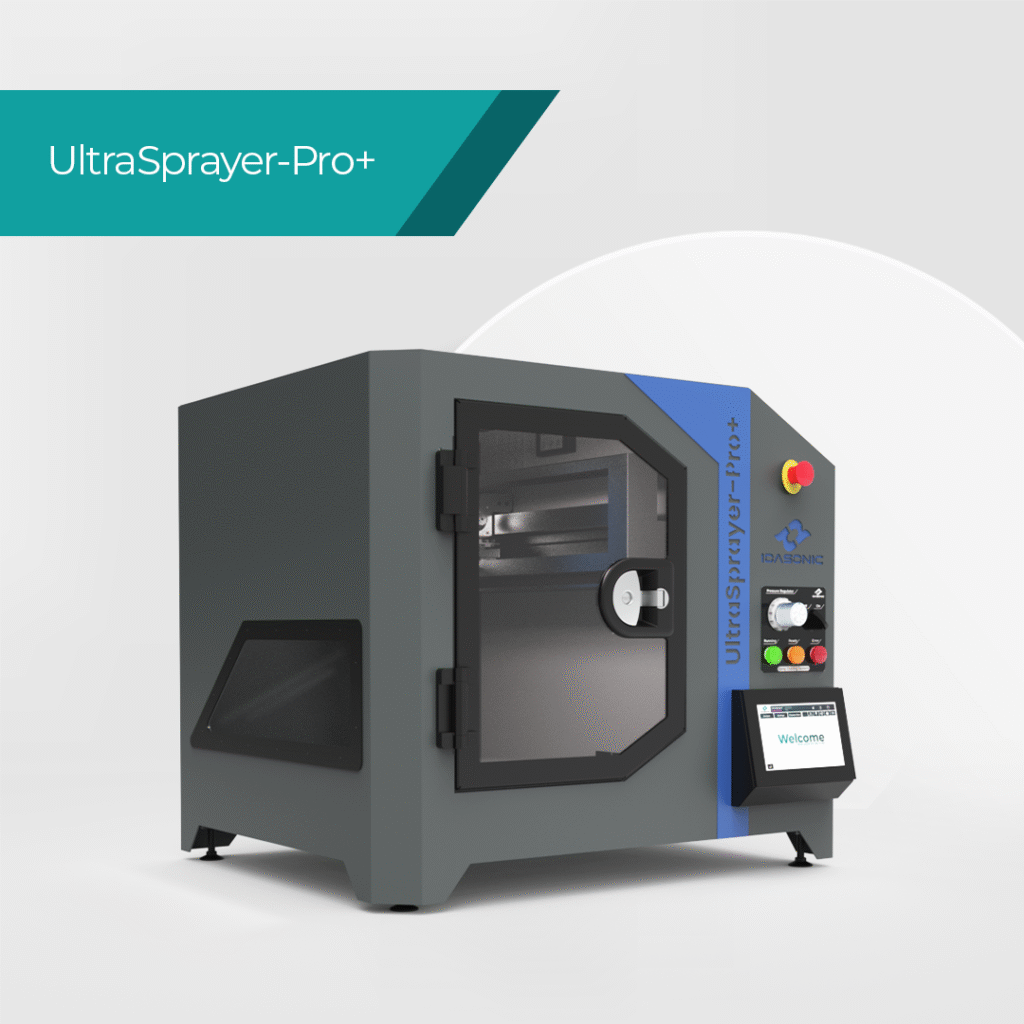

UltraSprayer®-Pro+ is the pinnacle of lab-scale ultrasonic spray coating systems, designed for top-tier performance and versatility. This advanced system enables effective coating on a wide variety of surfaces, making it ideal for industries like solar cells, fuel cells, optoelectronic devices, semiconductor thin film coating, flexible electronics, textiles, medical, and defense.

UltraSprayer®-Pro+ is equipped with cutting-edge components tailored to meet the needs of modern research and development activities:

These features allow seamless management of thin film coating processes, giving users enhanced flexibility and precision through an intuitive touchscreen interface.

UltraSprayer®-Pro+ supports a variety of modular coating options to meet diverse application needs:

This adaptability ensures reliable results across various laboratory environments and industry-specific applications.

UltraSprayer®-Pro+ is designed for innovators and researchers who strive for excellence. Its advanced features and modular options make it the perfect tool for achieving consistent, high-quality results.

Contact us today to explore how UltraSprayer®-Pro+ can transform your projects and discover our specialized nanocoating solutions tailored for your needs!

Learn more about ultrasonic spray coating systems here.

| Control System | HMI/SCADA-controlled for real-time monitoring and system management |

| Power Supply | 200 V AC, 50 Hz, single-phase, Type F (Schuko) plug. |

| Screen | 7” touchscreen with user-centered interface design |

| Nozzle Motion | Automated 3D motion, 400 mm x 400 mm XY, Z-axis 50–200 mm |

| Ultrasonic Spray Nozzle | IdaMist® Ultrasonic Atomizer (100 kHz) with vortex air shaper |

| Heating Plate | IdaCalor-HT3535, Max Temp: 500°C, 350 mm x 350 mm |

| Vacuum Plate | IdaVac-RT3535, 350 mm x 350 mm, heated (max. 200°C) or non-heated |

| Liquid Delivery | Three-channel syringe pump, up to 60 ml syringes |

| Micro Syringe Pump (optional) | Integrated at nozzle for precise micro-volume dispensing (optional) |

| Flow Rate Range | Min: 17.9 nl/min (with BD 1ml syringe) Max: 84 ml/min (with BD 60ml syringe) |

| Additional Features | Environmental Monitoring, LED Lighting |

| Dimensions | 950 mm x 1000 mm x 850 mm |

| Carrier Gas Regulation | Manual pressure regulator |

| Certification | CE, ISO 9001:2015 |

"Since its installation in our lab in Metallurgical and Materials Engineering Department, the UltraSprayer-Starter system has not only facilitated our ongoing research on solar cells and photocatalyst thin films, but also significantly expanded our research capabilities by enabling the coating of metallic materials. Its ease of use in non-vacuum environments, advanced electronic infrastructure, and suitability for large-area deposition have made it an integral part of both undergraduate and academic research activities. The system has found widespread use among our students and academic staff alike, supporting a diverse range of experimental studies."

“In our research group, we have been actively using IDASONIC’s triple syringe pump in our spray coating system, and we are very satisfied with the results. For our work on semiconductor thin films—particularly oxide- and sulfide-based compounds for optoelectronic circuit elements—the pump’s precise and stable flow control provides a significant advantage. Even at very low flow rates, it ensures consistent and reproducible performance. This reliability has improved both the accuracy of our experiments and the overall quality of the thin films we produce. IDASONIC’s syringe pump has become an essential tool for our research activities.”

“In our research group at Çanakkale Onsekiz Mart University, we are using IDASONIC’s NanoWeaver® Pro electrospinning system for our studies on advanced wound dressings, particularly targeting diabetic wound healing applications. The system’s high precision, stability, and versatility in nanofiber production allow us to design and fabricate functional wound dressings with controlled morphology and tailored properties. This capability significantly enhances the quality and reproducibility of our experimental results. IDASONIC’s NanoWeaver® Pro has become a key technology enabling us to advance our research on innovative solutions for diabetic wound treatment.”

“At the Department of Metallurgical and Materials Engineering, we are using IDASONIC’s UltraSprayer® Pro ultrasonic spray coating system for our research on transparent conductive oxide (TCO) thin films, particularly aluminum-doped zinc oxide (AZO). The system provides excellent control over film thickness, uniformity, and reproducibility, which are critical parameters in our work. With UltraSprayer® Pro, we have been able to produce high-quality AZO coatings with improved optical and electrical properties, directly supporting our research on next-generation functional materials. The device has proven to be a reliable and indispensable part of our laboratory.”

With the introduction of the Electrospinning System into our laboratory, we immediately noticed a positive shift in our research workflow. Its compact structure and intuitive controls allowed our graduate students to start experiments quickly without the need for extensive training. The device enabled us to fabricate uniform and reproducible nanofiber structures, which had been difficult to achieve with traditional methods. For research groups engaged in nanomaterials, biomedical applications, or advanced composites, this system stands out as a practical educational platform and an innovative tool that enhances both teaching and research. In addition, the responsive technical support and service provided gave us extra confidence, ensuring that we could focus on our experiments without interruptions.

“At COBILTUM, we have been using the NanoWeaver® Pro system in our studies on smart windows, wound dressings, drug delivery systems, and various nanofiber-based coatings. The system offers reliable performance and flexibility, which helps us to work on both materials science and biomedical applications. Its capability to produce uniform nanofibers with controlled properties has made it a practical tool for our research group, supporting different projects in a consistent way.”

We are excited to share new progress from our biomaterials surface engineering studies. Using a controlled ultrasonic spray coating approach,...

We are excited to share new progress from our biomaterials surface engineering studies. Using a controlled ultrasonic spray coating approach,...

Electrospinning is at the core of next-generation material science. With the ability to produce uniform, functional nanofibers, it is revolutionizing...

The UltraSprayer®-Pro is designed to handle a wide range of materials, including conductive inks, nanoparticles, polymers, bio-coatings, and other specialty solutions commonly used in solar cells, fuel cells, medical devices, and electronics.

Yes. While UltraSprayer®-Pro is optimized for research and development, its precision, flexibility, and modular coating capabilities make it well-suited for pilot-scale production and prototyping.

The 3-channel syringe pump allows users to dispense multiple fluids either simultaneously or sequentially, enabling multi-layer coatings, gradient films, or flexible process control without hardware changes.

Yes. The system’s XYZ mobility and modular accessories (e.g., stent, catheter, and in-tube coating modules) enable precise coating of irregular and complex geometries.

For company news, product updates and releases, subscribe to our newsletter.

© 2016 IDASONIC: Ultrasonic Spray Coating & Electrospinning Systems

Privacy Policy – Terms and Conditions – Cookie Declaration