Discover how nanocoating technologies revolutionize hydrogen energy systems. Enhance durability, efficiency, and corrosion resistance with Idasonic’s precision surface engineering solutions.

IDASONIC at the Hydrogen Technology World Expo 2025!

The world’s energy transformation is accelerating. As countries, industries, and research institutions move away from fossil fuels, their focus increasingly shifts toward hydrogen technologies. One of the most significant global gatherings driving this transition is the Hydrogen Technology World Expo, held annually in Hamburg, Germany.

This year, from October 21–23, 2025, the exhibition will once again serve as a prestigious platform showcasing the latest advancements in hydrogen production, storage, transportation, and utilization technologies.

As IDASONIC, we will attend the event as visitors, aiming to further develop the solutions we offer to the energy sector through our ultrasonic spray coating and electrospinning nanofiber production technologies.

Nanofibers in Cosmetics: The Science Behind Next-Generation Beauty Solutions

In recent years, nanofiber technology has revolutionized the cosmetic industry by providing new approaches for skin regeneration, active ingredient delivery, and anti-aging treatments. Through electrospinning, researchers can fabricate ultra-fine polymer fibers with diameters ranging from tens to hundreds of nanometers. These nanofibers exhibit an exceptional surface-area-to-volume ratio, porosity, and biocompatibility, enabling superior absorption and controlled release of cosmetic actives.

The integration of nanofiber technology in cosmetics offers several benefits:

High active loading efficiency and stability of sensitive ingredients.

Customized release kinetics, ranging from rapid hydration to prolonged delivery.

Minimal use of preservatives and solvents, supporting clean beauty standards.

Eco-friendly production using biodegradable polymers such as PVA, PLA, and HA.

As the demand for sustainable and science-based skincare grows, nanofiber cosmetics represent the bridge between cosmetic chemistry and biomedical engineering

Ultrasonic Spraying: Transforming Coating Technologies

By using high-frequency vibrations, ultrasonic spraying produces a fine mist of uniform droplets, enabling precise coatings at the nano- and microscale. This method is increasingly used in protective coatings, nanofiber filters, energy systems, and biomedical devices. The benefits of ultrasonic spraying technology extend across protective coatings, electronics, energy, nanofiber filters, and medical solutions.

Protective Coatings: Uniform coatings for ballistic armor, drones, and aircraft surfaces, providing enhanced durability and lightweight protection.

Electronic and Sensor Protection: Thin film coatings for radar, IR sensors, and PCBs, shielding sensitive components from moisture, salt, and chemical damage.

Energy and Fuel Cells: Advanced electrode coatings for military drones and portable field devices, improving efficiency and extending service life.

Nanofiber Filters: Integration with electrospinning for gas masks and NBC (Nuclear–Biological–Chemical) protection systems, enabling next-generation defense solutions.

Medical and Field Solutions: Nanofiber-based wound dressings, hemostatic coatings, and drug delivery systems, supporting rapid response in healthcare and field operations.

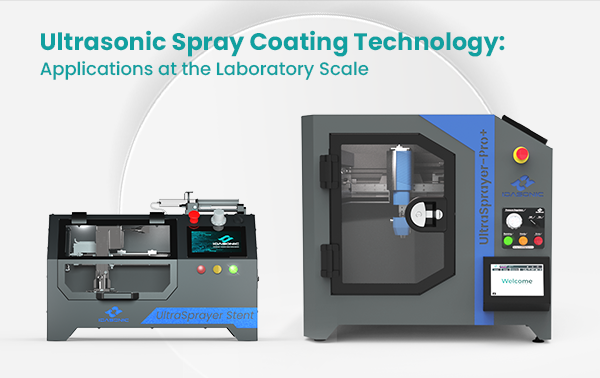

Ultrasonic Spray Coating Technology: Applications at the Laboratory Scale

Ultrasonic spray coating is based on the principle of spraying liquid solutions onto surfaces in a controlled manner by breaking them down into homogeneous, fine droplets using high-frequency vibrations. This method ensures:

Reduced material waste

Increased film homogeneity

Repeatable experimental results are obtained

For laboratory researchers, these features mean both reliable data and efficient resource utilization.

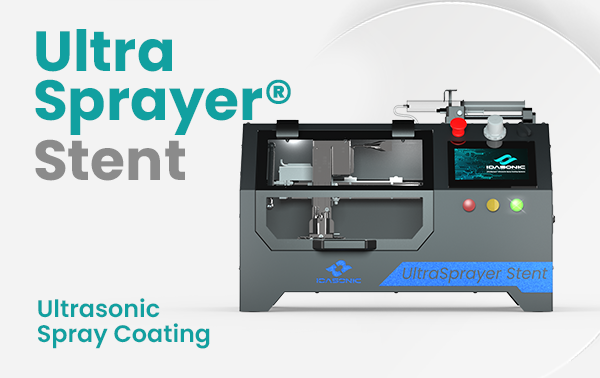

Leading Technology in Medical Device Coating Solutions: Ultrasonic Stent Coating with UltraSprayer®

Ultrasonic spray coating is a cutting-edge technique that enables precise, uniform, and reproducible coating of cardiovascular stents. Unlike traditional dip-coating or air-spray methods, ultrasonic atomization produces microdroplets that allow for superior drug distribution, minimal material loss, and enhanced control over coating thickness.

In modern medicine, stent coating technology plays a vital role in the long-term success of cardiovascular implants. Proper coating not only improves biocompatibility but also enhances drug-eluting stent (DES) performance, ensuring controlled therapeutic release and minimizing restenosis risk.

Nanofiber Production with Electrospinning: Materials of the Future

Electrospinning will continue to revolutionize sectors such as filtration, medical devices, energy storage, and smart textiles. A growing trend is the use of bio-based and sustainable nanofiber production, aligning with global environmental goals.

Nanofibers produced by electrospinning are opening new horizons for high-performance, functional, and innovative materials. From laboratory research to industrial production, IDASONIC’s NanoWeaver® solutions provide precise, reliable, and scalable nanofiber manufacturing.

Electrospinning and Nanofiber Production with the NanoWeaver®-Starter

Electrospinning is an advanced nanotechnology method used to produce ultra-thin nanofibers with diameters ranging from a few nanometers to several micrometers. By applying a high voltage electric field to a polymer solution, electrospinning creates continuous fibers that form nanofiber membranes. These membranes have a high surface-to-volume ratio, tunable porosity, and unique structural properties, making them ideal for applications such as filtration, biomedical applications, drug delivery, tissue engineering, air filtration, and water filtration.

“Electrospinning is an advanced nanotechnology method used to produce ultra-thin nanofibers with diameters ranging from a few nanometers to several micrometers.”

IDASONIC Showcases Its Game-Changing Technologies in the Defense Sector

IDASONIC, a leading high-tech company, has released a new brochure highlighting its cutting-edge nanocoating and nanofiber technologies developed specifically for critical defense applications.

IDASONIC UltraSprayer® Essential at Karlsruhe Institute of Technology!

The UltraSprayer Essential model developed byIDASONIC has been delivered to Karlsruhe Institute of Technology (KIT), one of Europe’s leading research institutions. Our device will be actively used in the scientific studies conducted by Researcher Jan Bruder.