Ultrasonic spray nanocoating technology applies nano-sized materials onto textile surfaces, revolutionizing the textile industry nanocoating processes. As a result, this advanced method enhances product performance, comfort, and durability, making it an increasingly favored solution in the industry.

By leveraging this innovative technique, manufacturers can meet evolving customer demands and achieve superior product quality. Furthermore, our UltraSprayer-Pro+® Device, specifically designed for R&D and small-scale production, supports the development of advanced textile products with key features such as:

Additionally, for scalability, our UltraSprayer-Pilot® and UltraSprayer-Industrial® devices enable pilot and large-scale manufacturing. These solutions empower textile brands to maintain high-quality production while also adopting sustainable practices. Thus, they can excel in competitive markets.

For scalability, our UltraSprayer-Pilot® and UltraSprayer-Industrial® devices enable pilot and large-scale manufacturing. These solutions empower textile brands to maintain high-quality production and adopt sustainable practices while excelling in competitive markets.

This innovative approach redefines the possibilities in textile production, driving higher efficiency, improved quality, and reduced environmental impact. For customized solutions and more information, contact us today!

Explore the benefits of textile industry nanocoating with our innovative UltraSprayer® devices. Discover additional resources and applications here.

Nanofiber technology is transforming the textile industry nanofiber production processes with unmatched benefits and cutting-edge applications. Using electrospinning, polymer or polymer-like materials are drawn into nanometer-scale fibers, resulting in textiles with enhanced durability, functionality, and breathability. This advanced method ensures high-performance results, ideal for diverse textile applications. Additionally, nanofibers contribute to lightweight and flexible fabrics, enhancing user comfort while maintaining strength. Their eco-friendly production process aligns with sustainability goals, making nanofiber technology a cornerstone of the textile industry’s future innovations.

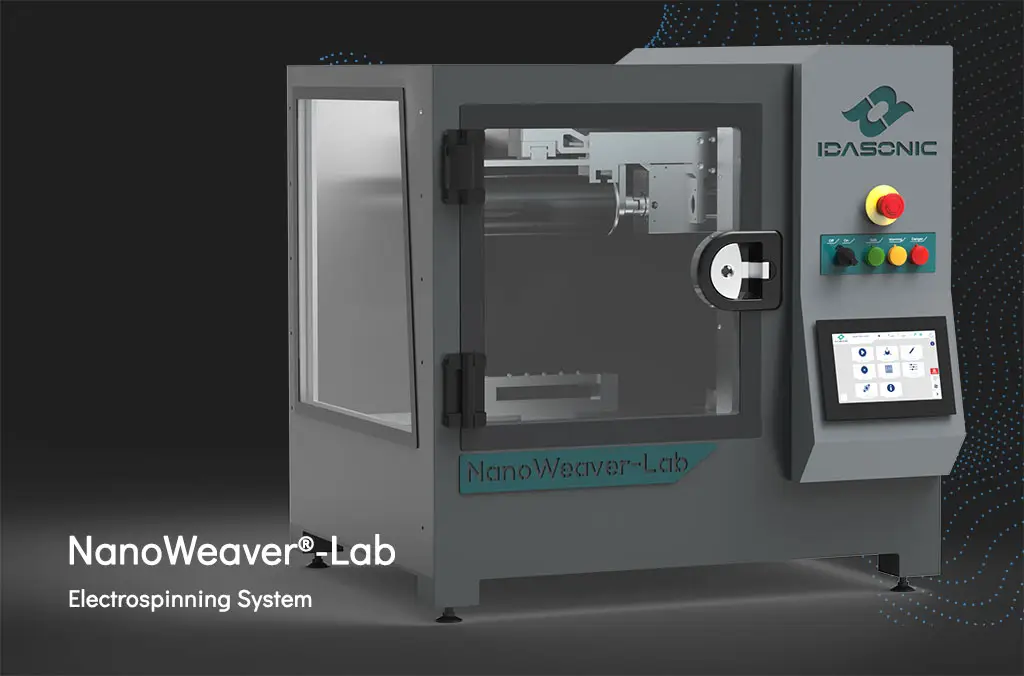

Our NanoWeaver®-Lab device is specifically crafted for laboratory-scale nanofiber production, making it an indispensable tool for R&D efforts in the textile sector. This versatile system allows researchers to create nanofibers with exceptional properties like:

With these advancements, textile brands can develop innovative, high-performance products that meet demanding market requirements.

After completing the R&D phase, our NanoWeaver®-Fab and NanoWeaver®-Master devices seamlessly scale production to meet pilot and industrial-level demands. These systems ensure efficient, high-volume production, helping businesses bridge the gap between innovation and market entry.

At every stage, NanoWeaver® devices are engineered to meet customer-specific requirements. Designed with the highest quality standards, these systems optimize both production processes and product development. By prioritizing innovation and satisfaction, we empower textile brands to achieve measurable success in the textile industry nanofiber applications.

These features drive the increasing adoption of nanofiber technologies in the textile industry. By combining performance enhancements with eco-friendly practices, NanoWeaver® devices empower businesses to develop textiles that exceed expectations in functionality, comfort, and sustainability.

For more information, explore our Ultrasonic Spray Coating Devices and discover how NanoWeaver® can revolutionize your textile production processes.

Learn more about Nanocoating Technology for the Textile Industry here.

For company news, product updates and releases, subscribe to our newsletter.

© 2016 IDASONIC: Ultrasonic Spray Coating & Electrospinning Systems

Privacy Policy – Terms and Conditions – Cookie Declaration