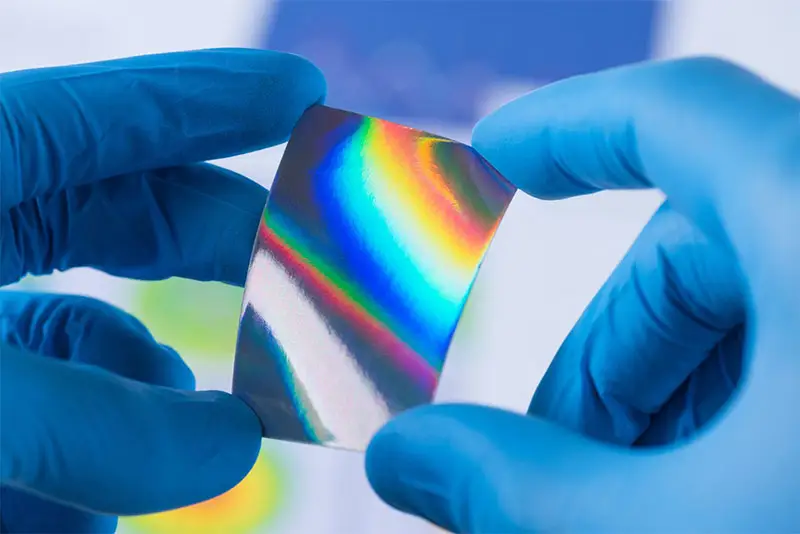

Our UltraSprayer® devices, ranging from laboratory scale to industrial scale, are designed for use in various industries such as solar cells, semiconductor devices, imaging technologies, precision sensors, and biomedical applications. For solar cell production, our devices optimize nanoscale material deposition processes to enhance cell performance and reduce production costs. In semiconductor device manufacturing, they can be used across a wide range of applications from transistors to microchips, enhancing product quality while reducing costs.

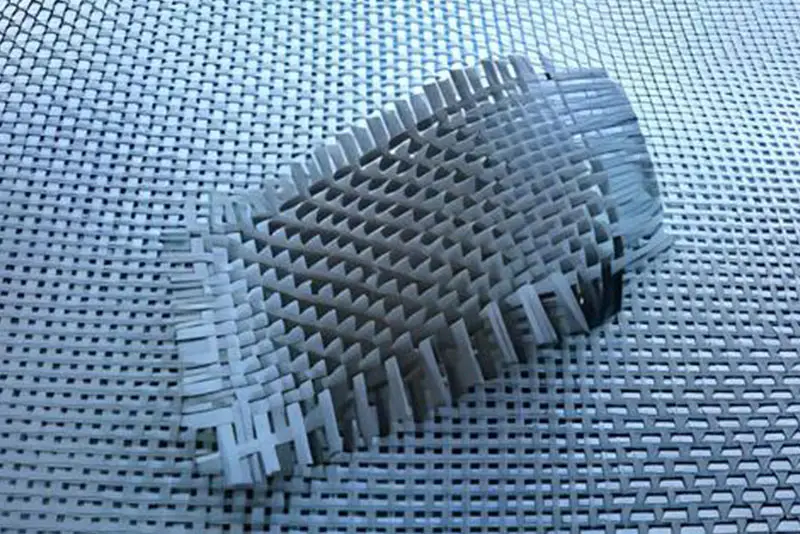

Ultrasonic spray nanocoating technology is an innovative solution that delivers excellent results in various applications within the filtration sector. Our UltraSprayer® devices, ranging from laboratory scale to industrial scale, can be used in a wide range of applications including water purification, air filtration, oil filtration, chemical and gas purification, and even medical device filtration.

Ultrasonic spray nanocoating technology is an innovative solution that delivers excellent results in various applications within the filtration sector. Our UltraSprayer® devices, ranging from laboratory scale to industrial scale, can be used in a wide range of applications including water purification, air filtration, oil filtration, chemical and gas purification, and even medical device filtration.

Ultrasonic spray nanocoating technique involves the application of nano-sized materials onto surfaces in the textile industry. This coating method is utilized to enhance the performance and properties of textile products. The ultrasonic spray nanocoating technology is gaining increasing attention in the textile industry due to its various advantages, contributing to the enhancement of product quality. Through this technology, the functionality, comfort, and durability of textile products can be significantly improved.

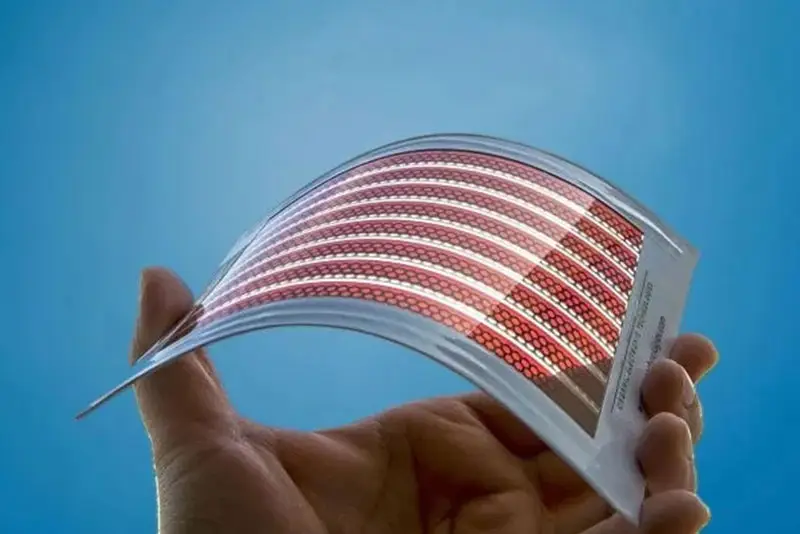

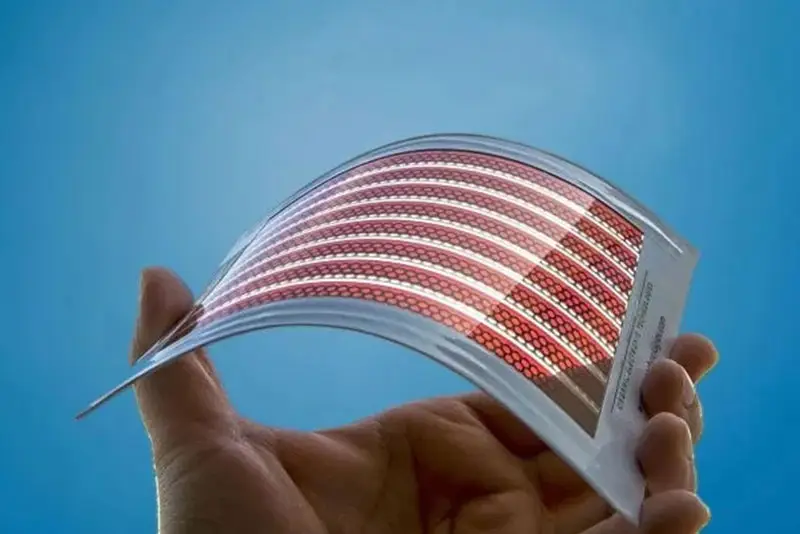

Our UltraSprayer® devices are meticulously designed to meet the precise and efficient coating requirements in thin film solar cell production processes.

Our UltraSprayer® devices are meticulously designed to meet the precise and efficient coating requirements in thin film solar cell production processes.

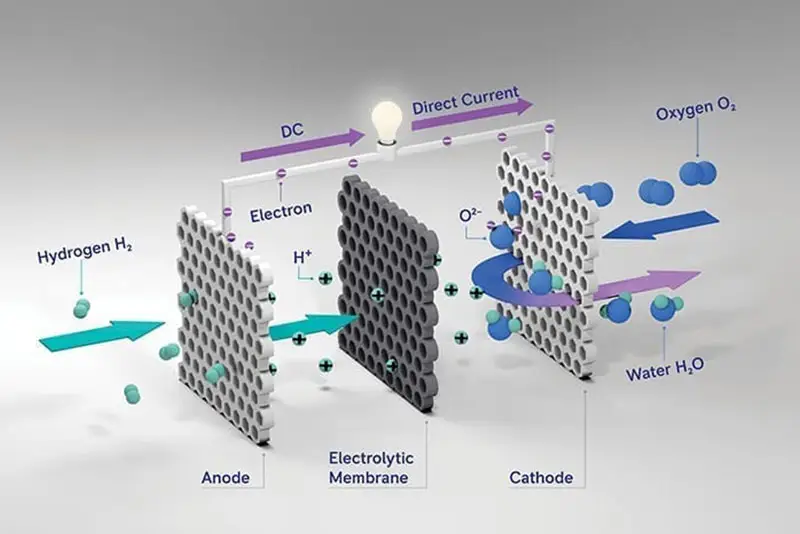

Are you ready to meet our UltraSprayer® Spray Coating Devices, offering cutting-edge solutions for fuel cells? Designed to deliver excellent results across a wide range of applications from laboratory to industrial scales, these devices are revolutionizing the fuel cell industry. Ultrasprayer harnesses the power of ultrasonic spray nanocoating technology to coat fuel cell components such as cathodes, anodes, membranes, flow channels, and substrates.

Our UltraSprayer-Med® spray coating systems, tailored to meet the needs of your research, are designed for leading-edge applications in the medical field. These systems are specifically optimized for coating critical medical devices such as stents and catheters, boasting state-of-the-art technology and superior performance.

Electrospinning technology, along with the production of nanofibers, presents substantial benefits across diverse applications within the medical sector. This innovative technique enables the transformation of polymers or polymer-like materials into fibers at the nanometer scale. The unique properties inherent in nanofibers offer numerous advantages, particularly in medical applications.

Our UltraSprayer-Med® spray coating systems, tailored to meet the needs of your research, are designed for leading-edge applications in the medical field. These systems are specifically optimized for coating critical medical devices such as stents and catheters, boasting state-of-the-art technology and superior performance.

Electrospinning technology, along with the production of nanofibers, presents substantial benefits across diverse applications within the medical sector. This innovative technique enables the transformation of polymers or polymer-like materials into fibers at the nanometer scale. The unique properties inherent in nanofibers offer numerous advantages, particularly in medical applications.

For company news, product updates and releases, subscribe to our newsletter.

© 2016 IDASONIC: Ultrasonic Spray Coating & Electrospinning Systems

Privacy Policy – Terms and Conditions – Cookie Declaration